Related searches

Smaller Footprints, Bigger Possibilities

Traditional car manufacturing required factories the size of small towns. But tomorrow’s plants are shrinking—and multiplying. Micro-factories, some as compact as a Walmart Supercenter, are popping up in suburbs and industrial parks. These facilities use modular assembly lines that can pivot between gas, hybrid, and electric models in days, not years.

This downsizing revolution cuts waste and energy use. Smaller car manufacturing hubs mean shorter supply routes, fewer carbon-spewing cargo ships, and less reliance on overseas parts. Imagine a factory that fits between a Costco and a coffee shop, building cars tailored to its neighborhood’s needs—snow-ready SUVs in Minnesota, sun-proof pickups in Arizona.

The New Currency of Car Manufacturing

Time is the Achilles’ heel of traditional car manufacturing. Designing a new model once took half a decade. Now, AI-driven prototyping and 3D printing slash development to months. On the factory floor, robots assemble battery packs in hours, not weeks, while augmented reality (AR) goggles guide workers through complex tasks with laser precision.

This speed isn’t just for automakers—it benefits buyers, too. Want a car in a custom color or with a unique trim? Car manufacturing 2.0 can deliver it in weeks, not months, turning mass production into “me-scale” production.

The Rise of Local Factories

Globalization once centralized car manufacturing in a few mega-hubs. But geopolitical tangles and pandemic snarls exposed the risks. The fix? Regional factories serving local markets. Tesla's “Gigafactory” model—which places plants near key buyers—is spreading. These localized hubs source materials from nearby mines and hire from surrounding towns, creating closed-loop ecosystems.

For drivers, proximity means transparency. Tour your car's birthplace on a weekend, watch it being built via live factory cams, or even volunteer to install a signature plate (for a fee). Car manufacturing becomes a community affair, not a distant corporate ritual.

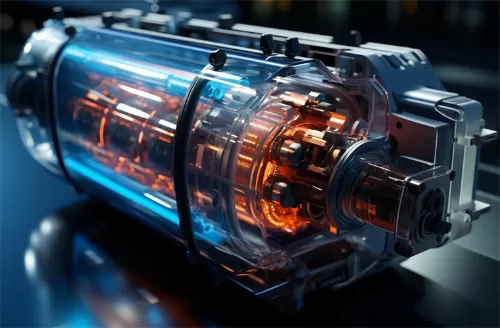

The Tech Fueling the Shift

Three innovations are rewriting car manufacturing rules:

Modular Platforms: Skateboard-like chassis that accommodate multiple body types.

Battery-as-a-Frame: Structural batteries that are part of the car's skeleton.

AI Quality Control: Cameras that spot defects faster than any human eye.

Together, they let small factories compete with giants.

The Human Touch in a Robotic Age

Smaller car manufacturing doesn't mean fewer jobs—it means different ones. Robots handle welding and painting, but skilled technicians program systems, maintain AI, and manage hyper-customized orders. These roles pay better than traditional assembly line work but demand tech fluency.

Unions are adapting, too. Training programs now focus on coding and robotics, preparing workers for a car manufacturing landscape where STEM skills trump wrench-turning.

The Roadblocks Ahead

Not all automakers are onboard. Legacy brands cling to old car manufacturing playbooks, fearing the cost of overhauling factories. There's also the challenge of scaling micro-factories without losing their nimbleness.

Yet consumer demand tilts the scales. Buyers increasingly want cars reflecting their values—local jobs, sustainability, personalization. Car manufacturing must evolve or risk irrelevance.

Conclusion

The era of monolithic, centralized car manufacturing is ending. In its place are nimble, eco-friendly factories that put consumers first. Whether you’re buying an electric SUV or a compact hybrid, these changes ensure your car is built smarter, faster, and with a smaller environmental footprint.

As technology evolves and demand shifts, the car manufacturing industry is proving that bigger isn't always better—closer, faster, and greener is the new gold standard.

Are Self-Driving Cars Safer Than HumansPicture this: It’s 8:15 a.m., and you’re balancing coffee, a conference call, and a backseat debate about why dinosaurs didn’t survive. Suddenly, a scooter cuts across three lanes. Your foot slams the brake—a reflex honed by years of driving. Now imagine your car handling that moment instead: no adrenaline, no panic, just sensors and algorithms reacting at lightning speed. This scenario plays out daily as autonomous driving quietly expands its reach. From Phoenix’s robotaxis to Shanghai’s self-parking sedans, vehicles without human drivers are no longer sci-fi. Yet a fundamental question lingers every time we see a car drive itself: Can machines truly outpace human skill behind the wheel? Autonomous driving technology promises safer roads, but the reality is far more nuanced than a simple “yes” or “no.”

Are Self-Driving Cars Safer Than HumansPicture this: It’s 8:15 a.m., and you’re balancing coffee, a conference call, and a backseat debate about why dinosaurs didn’t survive. Suddenly, a scooter cuts across three lanes. Your foot slams the brake—a reflex honed by years of driving. Now imagine your car handling that moment instead: no adrenaline, no panic, just sensors and algorithms reacting at lightning speed. This scenario plays out daily as autonomous driving quietly expands its reach. From Phoenix’s robotaxis to Shanghai’s self-parking sedans, vehicles without human drivers are no longer sci-fi. Yet a fundamental question lingers every time we see a car drive itself: Can machines truly outpace human skill behind the wheel? Autonomous driving technology promises safer roads, but the reality is far more nuanced than a simple “yes” or “no.” The Hidden Danger in Your Car: Why Cyberattacks Could Sabotage Automotive SafetyIn today's world, cars are no longer just mechanical devices; they're sophisticated computers on wheels. With internet connectivity, self - driving features, and intricate software systems, automotive safety is facing a new and menacing threat: cyber attacks. Hackers now have the ability to take control of crucial functions like brakes, steering, and even the entertainment system, putting drivers and passengers at risk. This growing danger is changing how we think about vehicle security and the steps needed to safeguard automotive safety.

The Hidden Danger in Your Car: Why Cyberattacks Could Sabotage Automotive SafetyIn today's world, cars are no longer just mechanical devices; they're sophisticated computers on wheels. With internet connectivity, self - driving features, and intricate software systems, automotive safety is facing a new and menacing threat: cyber attacks. Hackers now have the ability to take control of crucial functions like brakes, steering, and even the entertainment system, putting drivers and passengers at risk. This growing danger is changing how we think about vehicle security and the steps needed to safeguard automotive safety. Monthly Car Subscriptions: Affordable Freedom or Hidden CostsIn a world where streaming services and meal kits dominate, the auto industry is embracing a new trend: car subscription models. These services let you drive a vehicle for a flat monthly fee, promising flexibility, convenience, and freedom from long-term commitments. But as more Americans consider ditching traditional leases and loans, the question remains: Are these plans a financial lifesaver or a costly trap?

Monthly Car Subscriptions: Affordable Freedom or Hidden CostsIn a world where streaming services and meal kits dominate, the auto industry is embracing a new trend: car subscription models. These services let you drive a vehicle for a flat monthly fee, promising flexibility, convenience, and freedom from long-term commitments. But as more Americans consider ditching traditional leases and loans, the question remains: Are these plans a financial lifesaver or a costly trap?

The Hidden Costs of Hydrogen Fuel: What Drivers Need to Know Before SwitchingHydrogen Fuel Cell vehicles (HFCVs) are often marketed as the eco-friendly future of driving, combining zero emissions with gasoline-like convenience. But for everyday drivers, the true cost of adopting this technology goes beyond the sticker price. Before making the switch, understanding these hidden expenses—and how Hydrogen Fuel Cell systems uniquely contribute to them—is crucial.

The Hidden Costs of Hydrogen Fuel: What Drivers Need to Know Before SwitchingHydrogen Fuel Cell vehicles (HFCVs) are often marketed as the eco-friendly future of driving, combining zero emissions with gasoline-like convenience. But for everyday drivers, the true cost of adopting this technology goes beyond the sticker price. Before making the switch, understanding these hidden expenses—and how Hydrogen Fuel Cell systems uniquely contribute to them—is crucial. No More Pushy Salesmen: How Live Commerce Makes Car Buying TransparentFor decades, buying a car in America has been synonymous with high-pressure sales tactics, hidden fees, and hours spent haggling in dealerships. But a quiet revolution is underway, driven by Automotive Live Commerce—a blend of live streaming, virtual reality (VR), and real-time interaction that’s transforming the car-buying experience. This shift empowers consumers with transparency, convenience, and control, all while eliminating the stress of traditional salesmanship.

No More Pushy Salesmen: How Live Commerce Makes Car Buying TransparentFor decades, buying a car in America has been synonymous with high-pressure sales tactics, hidden fees, and hours spent haggling in dealerships. But a quiet revolution is underway, driven by Automotive Live Commerce—a blend of live streaming, virtual reality (VR), and real-time interaction that’s transforming the car-buying experience. This shift empowers consumers with transparency, convenience, and control, all while eliminating the stress of traditional salesmanship. Why Your Next Road Trip Needs a Co Pilot Named Intelligent DrivingAs Americans gear up for holiday road trips or summer adventures, the idea of a stress-free journey often collides with reality: navigating unfamiliar routes, managing traffic, and staying alert during long drives. Enter Intelligent Driving—a suite of advanced technologies transforming cars into copilots that enhance safety, efficiency, and peace of mind. While fully autonomous vehicles remain a work in progress, today’s Intelligent Driving systems offer practical tools to elevate your travel experience.

Why Your Next Road Trip Needs a Co Pilot Named Intelligent DrivingAs Americans gear up for holiday road trips or summer adventures, the idea of a stress-free journey often collides with reality: navigating unfamiliar routes, managing traffic, and staying alert during long drives. Enter Intelligent Driving—a suite of advanced technologies transforming cars into copilots that enhance safety, efficiency, and peace of mind. While fully autonomous vehicles remain a work in progress, today’s Intelligent Driving systems offer practical tools to elevate your travel experience. The Future of Car Factories: Smaller, Faster, and Closer to YouThe era of sprawling, smoke-belching car factories dominating city skylines is fading. A new blueprint for car manufacturing is emerging—one that prioritizes agility over enormity, customization over uniformity, and local roots over global supply chains. This shift isn’t just about building cars differently; it’s about reimagining how communities interact with the vehicles in their driveways.

The Future of Car Factories: Smaller, Faster, and Closer to YouThe era of sprawling, smoke-belching car factories dominating city skylines is fading. A new blueprint for car manufacturing is emerging—one that prioritizes agility over enormity, customization over uniformity, and local roots over global supply chains. This shift isn’t just about building cars differently; it’s about reimagining how communities interact with the vehicles in their driveways.